Metal stamping die is a crucial component in the manufacturing of precise metal parts, playing a vital role in the production of a wide range of products, from automobiles to electronic devices. In this article, we will explore the basic concepts, working principles, and applications of metal stamping die.

The metal stamping die, also known as metal forming die, is a precision-engineered tool used in metal stamping processes. It is designed to withstand the high pressure and temperature conditions required to shape metal sheets into desired shapes and sizes. The die is typically made of high-quality tool steel or other hard materials to ensure its durability and dimensional accuracy.

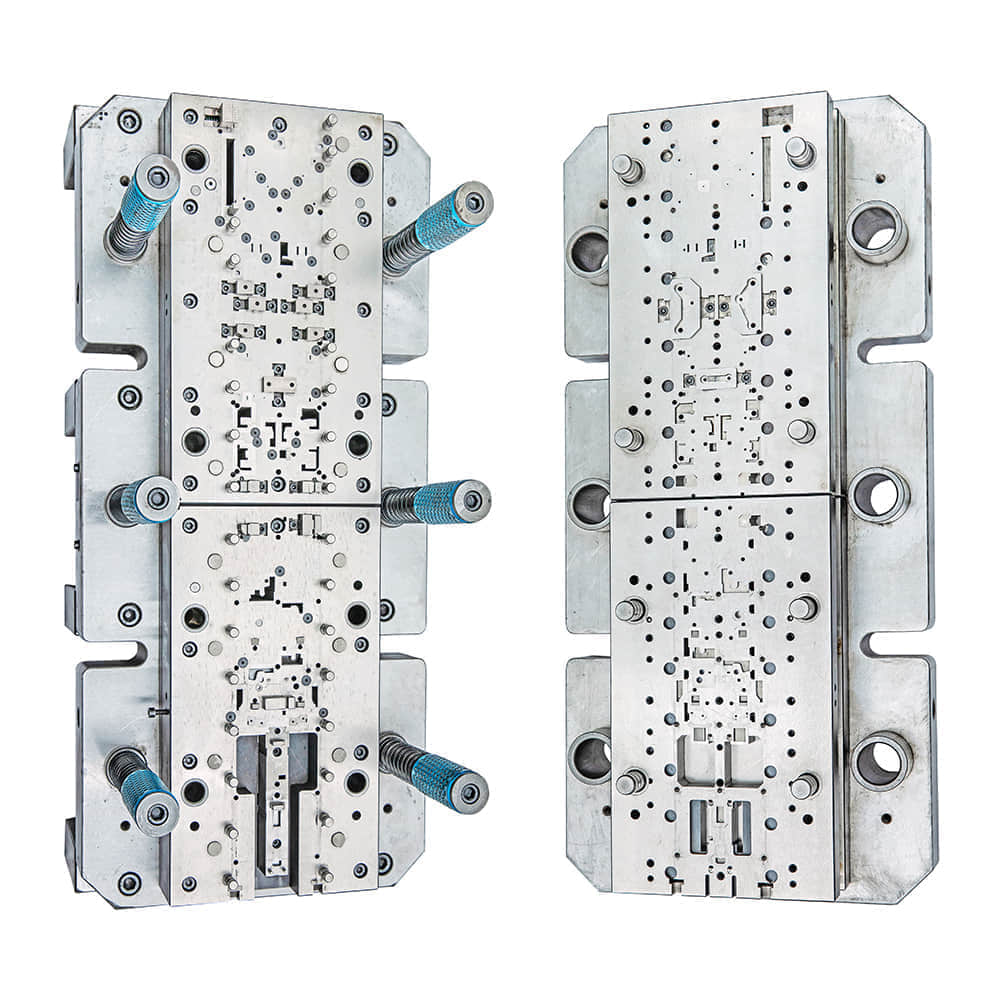

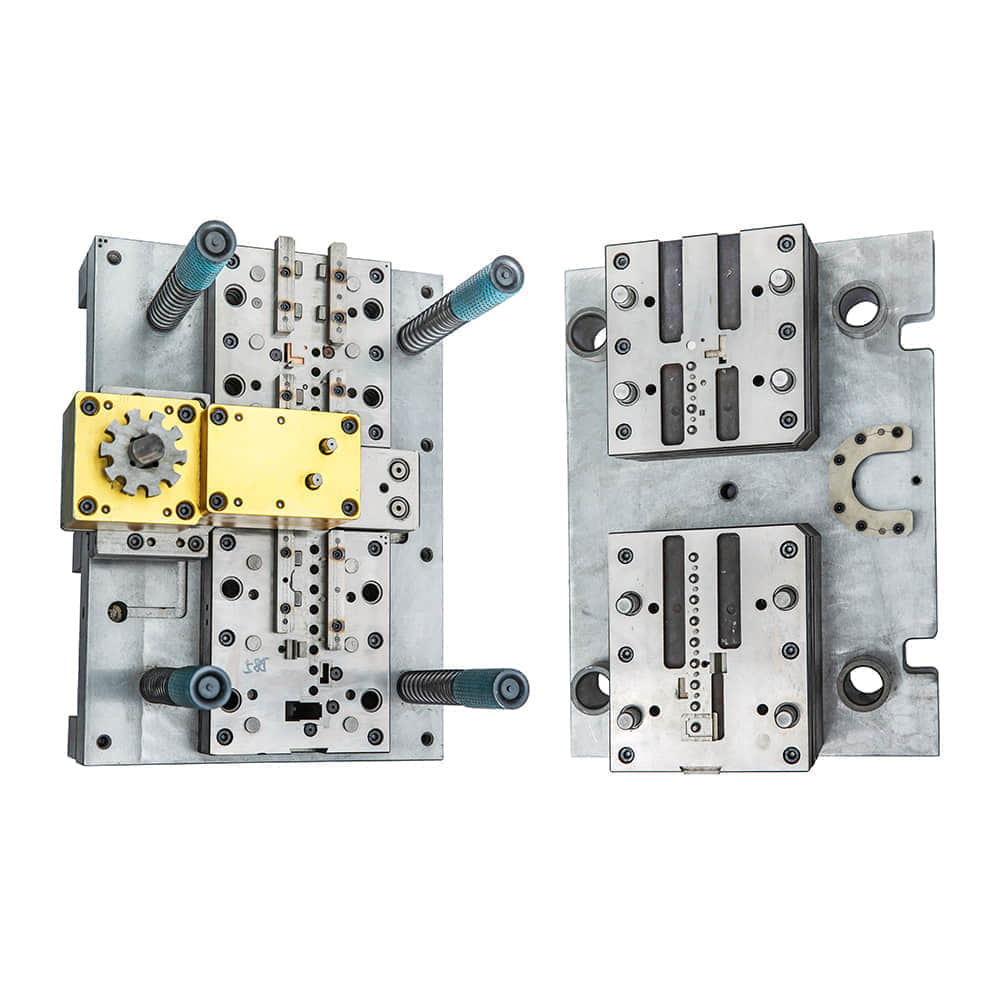

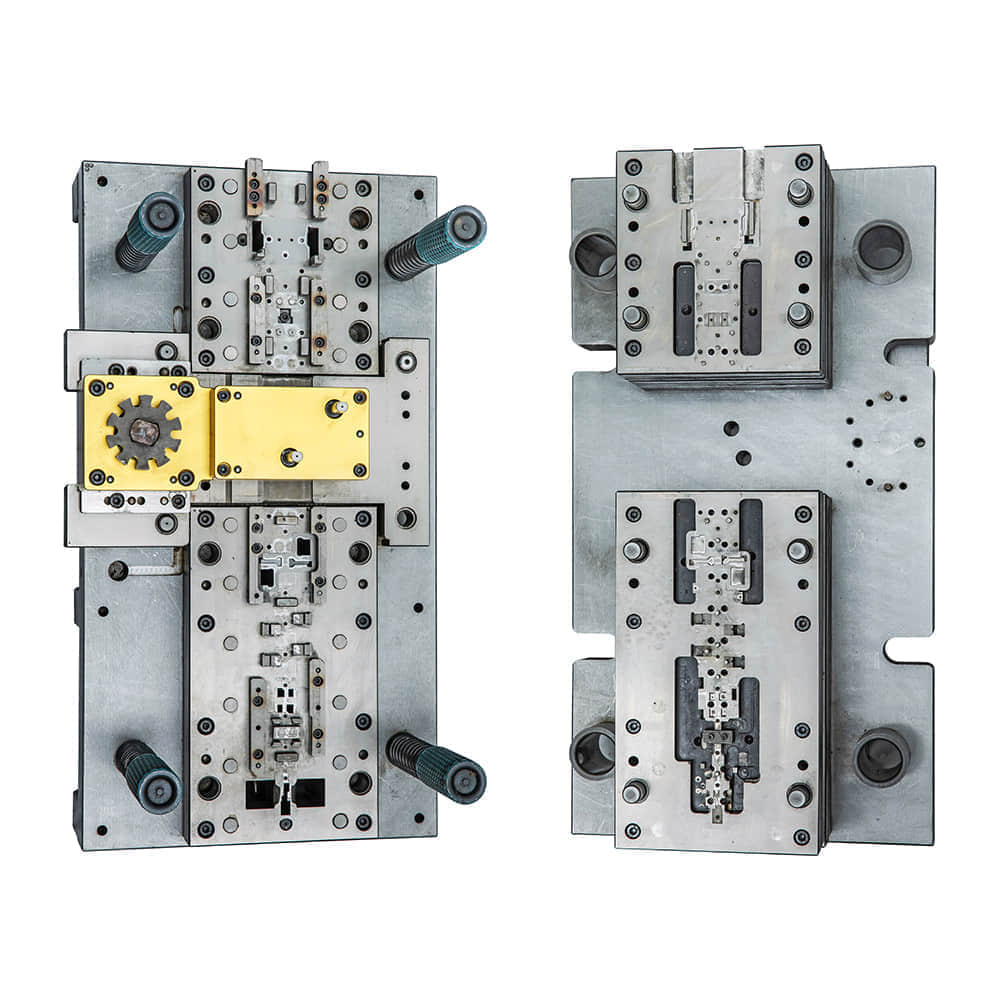

The metal stamping die consists of two main components: the upper die and the lower die. The upper die is fixed to the slide of the press machine, while the lower die is mounted on the bed of the press. During the stamping process, the upper and lower dies come together under extreme pressure to force the metal sheet into a desired shape. The design and manufacturing of metal stamping dies require precise calculations and sophisticated techniques to ensure accurate and repeatable results. The dies are typically custom-made according to the specific requirements of each production run. The design process involves several stages, including die design, material selection, heat treatment, assembly, and testing.

Leave a Reply